LYB is a leader in the global chemical industry creating solutions for everyday sustainable living. Through advanced technology and focused investments, we are enabling a circular and low carbon economy. Across all we do, we aim to unlock value for our customers, investors and society.

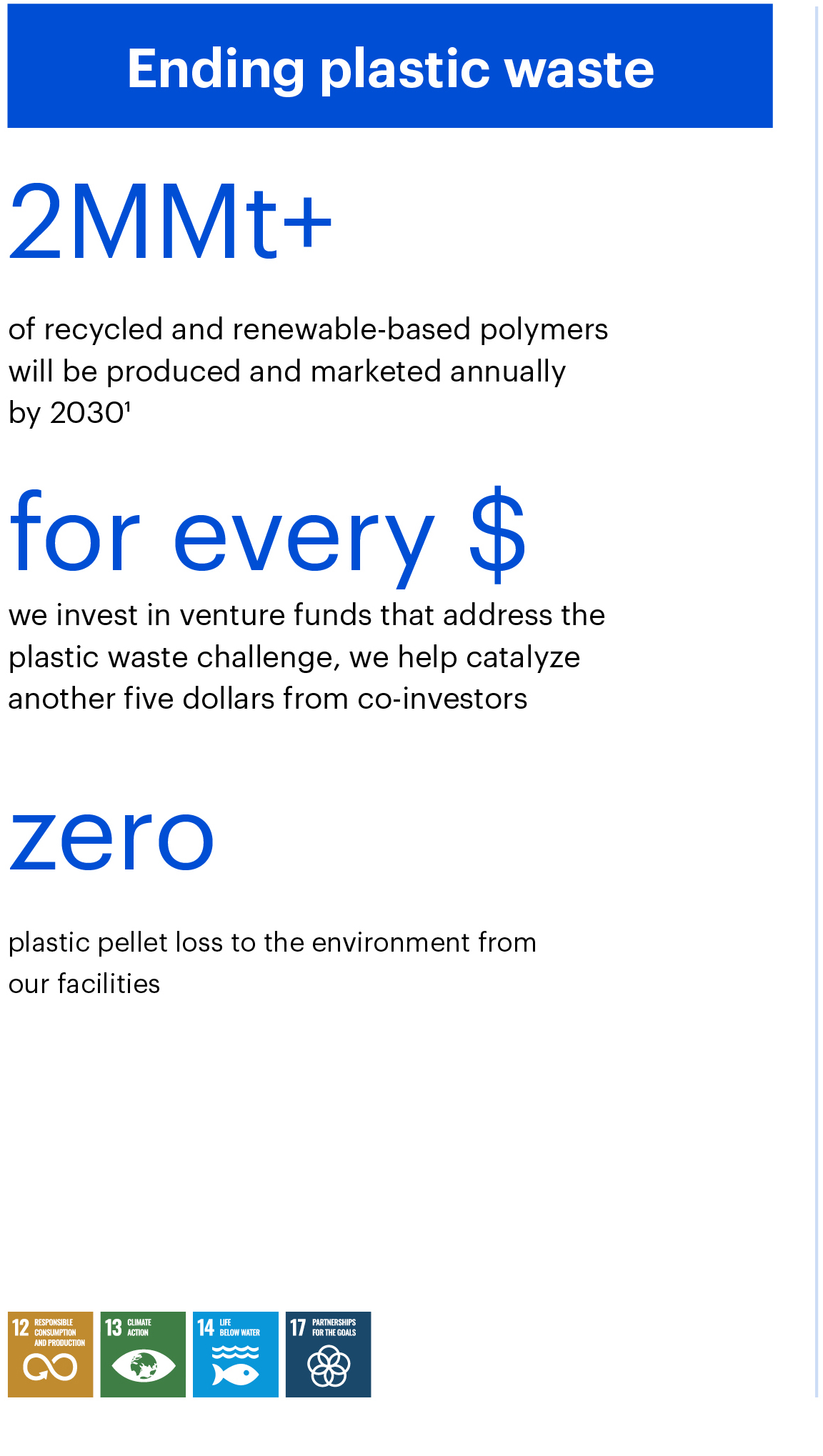

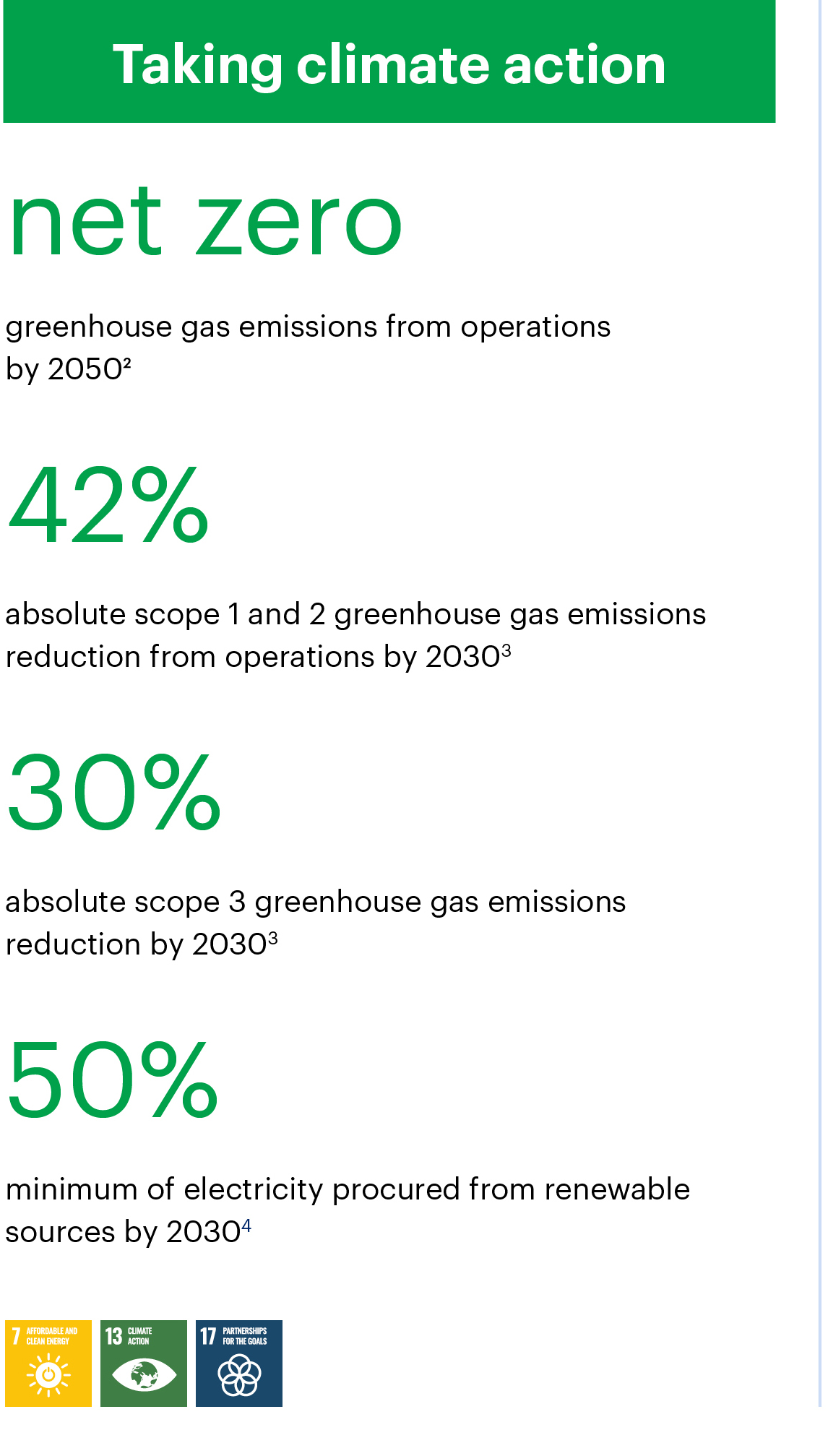

We have structured our sustainability approach around three global challenges: ending plastic waste, taking climate action and supporting a thriving society. This approach shapes how we manage our business and execute strategic objectives.