Hyperzone

In pilot plant tests, our new Hyperzone polyethylene (PE) proprietary technology demonstrated the ability to manufacture lighter weight products without compromising strength, ultimately reducing the amount of raw material required to manufacture end-use products.

High density polyethylene (HDPE) is used to make water and industrial pipes, bulk containers, household bottles, toys, outdoor playground equipment, and sporting equipment such as canoes and kayaks. HDPE can also be recycled. The HDPE made at our pilot plant using the Hyperzone PE technology has proved to be stronger, tougher and more stress crack-resistant when exposed to extreme environmental conditions when compared with other types of HDPE.

That means customers can use less raw material in certain applications to achieve differential product performance. In addition, lighter weight products reduce the energy needed to transport them, which decreases the associated carbon emissions.

Another exciting aspect is the ability to incorporate high levels of post-consumer recycled materials into the Hyperzone HDPE, making end-use products even more sustainable.

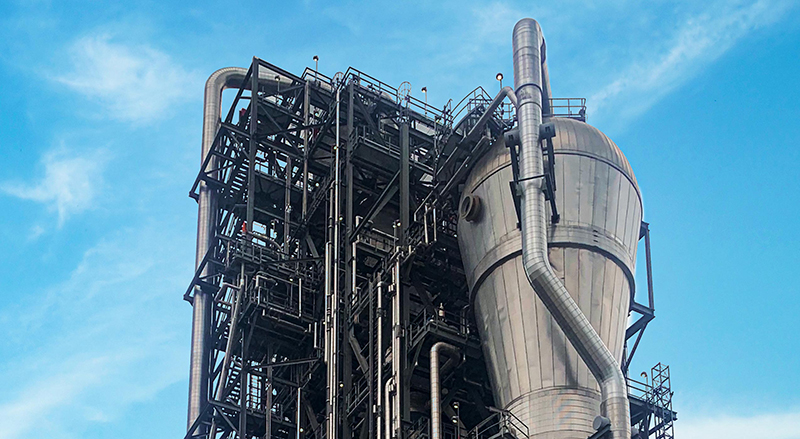

In 2019, we completed construction of the first commercial, world-scale Hyperzone PE plant in La Porte, Texas, and production began in the first quarter of 2020.

The technology took years to advance to commercialization and was a product of our global research and development teams in Ferrara, Italy; Frankfurt, Germany; Cincinnati, Ohio; and Houston, Texas.